Applications

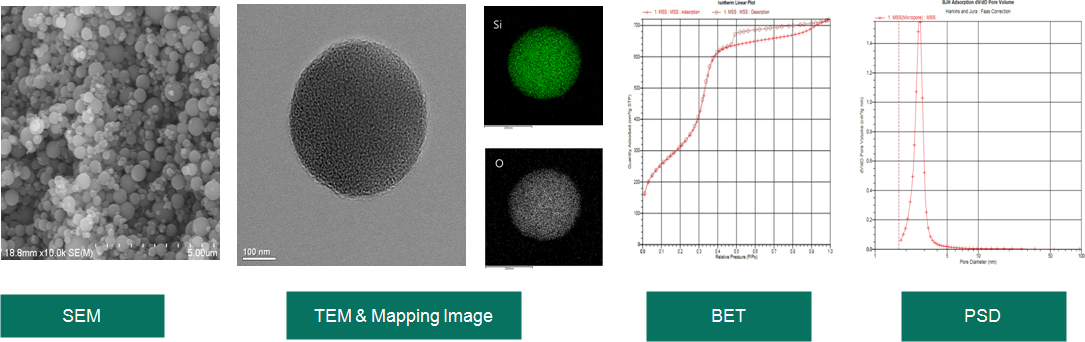

SMBTM 3 Property

1. Length/Diameter/Specific Surface Area are measured through SEM/TEM/BET & PSD respectively

2. Overall morphology is analyzed through SEM

| Product | Production description |

Pore Diameter (average) |

BET Surface Area (average) |

Pore Volume | Tap density |

|---|---|---|---|---|---|

SMB-3 |

Mesoporous Silica Nanoparticles (SiO2,99.9%), CEN Co., Ltd. |

3.45nm | >750m2/g | >1.0cm3/g | ~0.12g/cm3 |

SMBTM 3 vs MCM-41 NP

|

SMBTM | MCM-41 NP | |

|---|---|---|---|

| Structure | 3D structure | 2D structure | |

| BET Surface Area | > 750m2/g | 500~1,200m2/g | |

| Synthesis Method | Sustainable Methods (Aqueous Condition, Neutral, STP condition) |

Lots of Problem (Acidic or Basic condition, hydrothermal, Solvent need) |

|

| Pore Size | > 3.4nm | 2~4nm | |

| Pore Volume | > 1.0cm3/g | 0.7~1.2cm3/g | |

| Metal Encapsulation | Possible | Complicate or Very difficult | |

| Cost | Appropriate | Very Expensive |

Expectancy Effects of High Functional SMB-3 Composite Material

-

High Transparency

The dispersion of SMBTM 3 is outstanding, and the organic functionalization of the surface can be used to set the refractive index identically to the high molecular compound in order to maximize the transparency.

Heat Resistance

A synergy effect of the silica nano composite material containing a nanoporous air layer(enhances heat insulation, resist printing and glass transition temperature)

High Intensity

Such property can be induced based on the conflict with the stiff 3D linear-structured Mesoporous Silica Nanoparticle composite material

High Hardness

The aspect ratio indicated on the surface enhances the surface hardness through the large Mesoporous silica nanoparticle effect

Glare Prevention

An effect of the 3D nano structure/ pore(the haze value is indicated as well as the high transparency) –> properties of AG/AR